Manufacturing Facilities

Manufacturing facilities are required to adhere to strict federal guidelines and standards based on the nature of the products they produce. Exposure to byproducts and chemicals will damage typical concrete floors creating an environment for bacterial growth and degrading of the environment. Coatings to seal and protect the flooring create a barrier from contaminants - ensuring hygienic surfaces and the life of the floor.

Warehouse floors take a beating from floor jacks, fork lifts, shipping cartons, etc. Common shop paint needs to be reapplied every year and offers no real protection to the concrete. Epoxy Roll Down systems seal, protect and give longer life. Learn more >

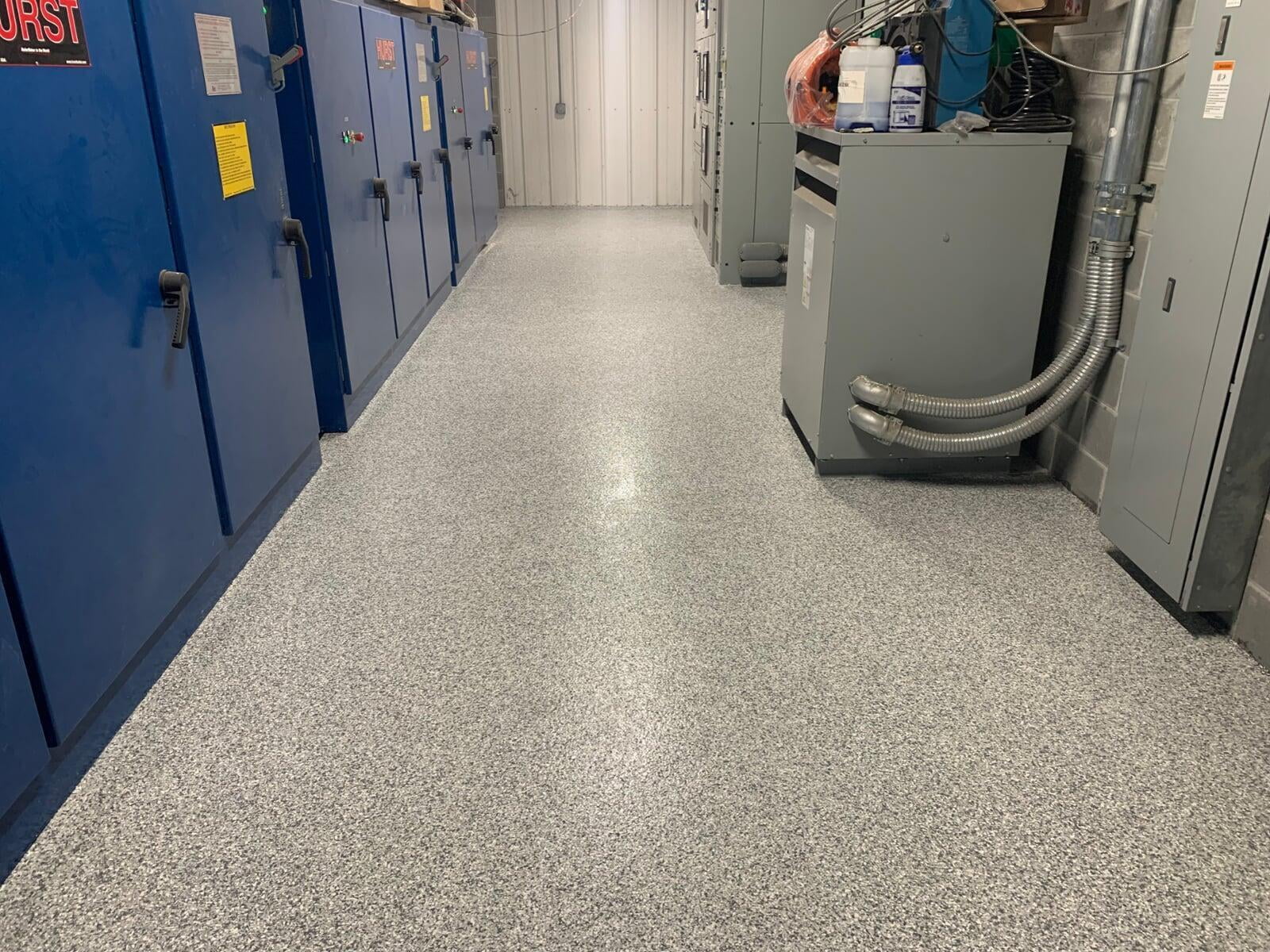

Most facilities have mechanical rooms with extreme environmental effects. Varying temperatures, chemical exposures and heavy machinery all have a great impact on the flooring. Resinous flooring systems offer longevity, safety and functionality in harsh environments. Learn more >

TRI Solutions can provide solutions for these common issues in manufacturing facilities :

Extreme temperatures, slip hazards, chemical exposures, abrasions and cracks, static and heavy traffic that damages the flooring.

OSHA regulations to have clearly marked areas where things go or don't go, danger areas, directional colors and product placement markings are required. Roll down epoxy coatings are available in a variety of colors. Learn more >

Anti static flooring is crucial in many manufacturing areas. Electronic, pharmaceutical, auto and general manufacturing areas can create a static charge that will trigger, ignite and cause explosions. TRI offers roll down epoxy coatings that are ESD compliant. Learn more >

Enhance the image of your facility and create a positive work environment for your employees. Reduce daily maintenance cost with the SaniGLAZE Tile and Grout Restoration Process. Learn more >